Standards and tolerances in Victoria ensure compliance with safety‚ quality‚ and regulatory requirements across industries. They provide guidelines for professionals to maintain consistency and integrity in their work‚ ensuring public trust and confidence in services and products.

1.1 Overview of Standards and Tolerances

Standards and tolerances in Victoria establish clear guidelines for industries to ensure safety‚ quality‚ and compliance. Standards outline specific requirements for materials‚ processes‚ and outcomes‚ while tolerances define acceptable deviations. These frameworks apply across construction‚ manufacturing‚ and service sectors‚ ensuring consistency and reliability. By adhering to these guidelines‚ professionals maintain public trust and confidence in the quality of services and products delivered.

1.2 Importance of Adhering to Standards

Adhering to standards and tolerances is crucial for ensuring safety‚ quality‚ and legal compliance in Victoria. Compliance builds public trust‚ minimizes risks‚ and avoids penalties. Standards promote consistency across industries‚ ensuring reliability in products and services. They also facilitate accountability and continuous improvement‚ safeguarding both professionals and consumers. By following these guidelines‚ industries maintain operational integrity and meet regulatory expectations‚ ultimately contributing to a safer and more efficient community.

Definitions and Key Concepts

This section defines key terms and explains fundamental concepts related to standards and tolerances in Victoria‚ providing a clear understanding of their roles and applications.

2.1 What Are Standards?

Standards are established guidelines or specifications that ensure consistency‚ quality‚ and safety in various industries. They are developed by regulatory bodies to define acceptable practices‚ materials‚ and processes‚ ensuring compliance with legal and ethical requirements. Standards provide a framework for professionals to follow‚ promoting reliability and uniformity in outcomes. Adherence to standards is crucial for maintaining public trust‚ avoiding legal penalties‚ and ensuring the integrity of products and services in Victoria.

2.2 Understanding Tolerances

Tolerances refer to the acceptable limits of deviation from specified standards or measurements. They define the maximum allowable variance in materials‚ processes‚ or final products to ensure quality‚ safety‚ and compliance. Tolerances are critical in maintaining consistency and preventing defects‚ particularly in construction and manufacturing. By setting clear boundaries‚ tolerances help professionals plan and execute projects effectively‚ balancing precision with practicality while adhering to regulatory requirements in Victoria.

2.3 Key Terminology

Key terminology includes standards‚ which are official guidelines for practices and materials‚ and tolerances‚ referring to permissible deviations. Compliance ensures adherence to these standards‚ while regulatory frameworks outline the legal and procedural requirements. Understanding these terms is essential for professionals to navigate and implement standards effectively in Victoria‚ ensuring quality‚ safety‚ and consistency across industries.

Regulatory Framework in Victoria

Victoria’s regulatory framework ensures adherence to standards and tolerances through governing bodies and legislation. It outlines roles‚ responsibilities‚ and compliance requirements‚ supported by authorities like the Victorian Building Authority.

3.1 Governing Bodies and Authorities

The regulatory framework in Victoria is overseen by key governing bodies‚ including the Victorian Building Authority (VBA)‚ which enforces building codes and standards. Other authorities like WorkSafe Victoria and the Environment Protection Authority (EPA) also play crucial roles in setting and monitoring compliance with industry-specific tolerances and standards. These bodies ensure that professionals adhere to legal and safety requirements‚ maintaining public trust and upholding the integrity of services and infrastructure across the state.

3.2 Relevant Legislation and Acts

Victoria’s standards and tolerances are governed by key legislation‚ including the Building Act 1993‚ which regulates building practices and compliance. The Act ensures adherence to safety and quality standards‚ while other laws like the Environment Protection Act 1970 and the Occupational Health and Safety Act 2004 address environmental and workplace safety. These legislative frameworks provide the foundation for enforcing standards‚ ensuring public health‚ safety‚ and environmental protection across various industries in Victoria.

3.3 Role of the Victorian Building Authority

The Victorian Building Authority (VBA) is responsible for regulating and enforcing building standards across Victoria. It ensures compliance with legislation‚ codes‚ and tolerances‚ promoting safe and sustainable building practices. The VBA oversees the registration of building practitioners‚ investigates complaints‚ and provides guidance on meeting regulatory requirements. By maintaining high standards‚ the VBA protects consumers and upholds public confidence in the building industry‚ ensuring that construction projects adhere to both legal and quality expectations.

Standards for Building and Construction

Building and construction standards in Victoria govern materials‚ structural integrity‚ and safety protocols. They ensure compliance with codes‚ promoting durability and adherence to regulatory requirements.

4.1 Structural Integrity Standards

Structural integrity standards in Victoria ensure buildings and infrastructure can withstand loads and stresses safely. These standards outline requirements for design‚ materials‚ and construction practices to prevent failures. Engineers and builders must comply with codes like AS 4100 for steel structures and AS 3600 for concrete‚ ensuring durability and safety. Regular inspections and testing are mandated to verify compliance‚ protecting public safety and maintaining trust in constructed environments. Non-compliance risks structural failure and legal consequences.

4.2 Material Quality and Compliance

Material quality and compliance in Victoria are governed by strict standards to ensure safety and durability. Materials must meet specific benchmarks‚ such as strength‚ durability‚ and fire resistance‚ as outlined in Australian Standards like AS/NZS 2588 for concrete and AS 3678 for steel. Compliance requires testing‚ certification‚ and third-party verification to confirm materials meet regulatory demands. Non-compliance can lead to structural risks‚ legal penalties‚ and reputational damage‚ emphasizing the importance of adhering to these rigorous standards.

4.3 Tolerances in Construction

Tolerances in construction are critical to balancing precision and practicality. They define acceptable deviations in measurements to accommodate real-world limitations. Properly set tolerances ensure structural integrity‚ safety‚ and functionality while avoiding unnecessary costs. In Victoria‚ construction tolerances are outlined in standards like AS 3600 for concrete structures and AS 4100 for steel structures. Adhering to these ensures compliance‚ reduces defects‚ and maintains public safety. Non-compliance can result in costly rework or legal issues.

Tolerances in Specific Trades

Tolerances vary across trades‚ ensuring safety and compliance. Victorian standards define specific limits for carpentry‚ plumbing‚ and electrical work‚ maintaining quality and public trust.

5.1 Tolerances in Carpentry and Joinery

Tolerances in carpentry and joinery are critical for ensuring structural integrity and aesthetic appeal. Victorian standards specify acceptable deviations for joints‚ alignments‚ and material dimensions‚ ensuring safety and durability. Proper adherence to these tolerances prevents issues like misaligned frames or uneven surfaces‚ maintaining compliance and quality in construction projects. Non-compliance can lead to structural weaknesses and safety hazards‚ emphasizing the importance of precise craftsmanship and adherence to regulations.

5.2 Tolerances in Plumbing and Pipefitting

Tolerances in plumbing and pipefitting are essential for ensuring safe and efficient water and gas systems. Victorian standards outline precise allowances for pipe fitting‚ connections‚ and alignments to prevent leaks and blockages. Proper adherence ensures water quality‚ pressure stability‚ and compliance with health regulations. Non-compliance can lead to system failures‚ safety risks‚ and environmental hazards‚ making accurate measurements and adherence to standards critical in plumbing installations across Victoria.

5.3 Tolerances in Electrical Installations

Tolerances in electrical installations are critical for ensuring safety‚ reliability‚ and compliance with Victorian standards. They dictate acceptable ranges for voltage‚ current‚ and resistance‚ as well as wiring and circuit accuracy. Adherence to AS/NZS 3000 standards ensures minimal risk of electrical hazards‚ such as shocks or fires. Proper tolerances also guarantee efficient energy distribution and equipment performance. Non-compliance can lead to system failures‚ safety risks‚ and legal penalties‚ emphasizing the importance of precise installations and regular inspections.

Measuring and Verifying Compliance

Measuring and verifying compliance ensures adherence to Victorian standards and tolerances. It involves systematic inspections‚ accurate measurements‚ and thorough documentation to confirm that all requirements are met effectively.

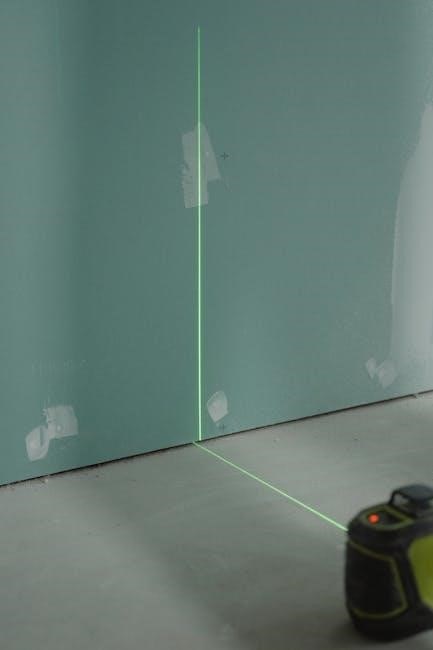

6.1 Tools and Techniques for Measurement

Accurate measurement tools are essential for verifying compliance with Victorian standards. Common tools include digital calipers‚ laser levels‚ and precision gauges. Techniques involve systematic inspections‚ comparing measurements against approved plans‚ and documenting results. Regular calibration of tools ensures reliability. Advanced software can analyze data for compliance. Proper training in measurement techniques is critical to avoid errors. Consistent methods help maintain accuracy and consistency across projects‚ ensuring adherence to established tolerances and standards effectively.

6.2 Documentation and Reporting

Accurate documentation is crucial for compliance verification. Records should include measurement results‚ inspection reports‚ and compliance certificates. Digital tools and checklists streamline reporting processes. Proper documentation ensures transparency‚ traceability‚ and accountability. Reports must adhere to formatting standards‚ including clarity and accessibility. Regular audits of documentation ensure accuracy and compliance with Victorian regulations. Proper archiving of records facilitates future reference and audits‚ maintaining integrity and accountability throughout the project lifecycle.

Best Practices for Adhering to Standards

Implement best practices by ensuring thorough planning‚ ongoing training‚ and regular monitoring. Maintain accurate documentation and collaborate with regulators to ensure compliance with Victorian standards and tolerances effectively.

7.1 Planning and Design Phase

The planning and design phase is critical for ensuring compliance with Victorian standards and tolerances. Begin by defining clear project objectives and conducting feasibility studies to identify potential risks. Develop detailed designs that align with regulatory requirements‚ ensuring materials and methodologies meet specified tolerances. Engage stakeholders early to address compliance issues proactively. Regularly review designs against Victorian Building Authority guidelines to avoid deviations. Effective planning minimizes errors‚ ensuring projects are both functional and compliant from the outset.

7.2 Execution and Monitoring

During execution‚ ensure all activities align with approved designs and standards. Utilize tools and techniques for precise measurement and compliance verification. Maintain detailed documentation to track progress and deviations. Regular monitoring helps identify and address issues promptly‚ preventing non-compliance. Continuous communication between teams fosters collaboration and adherence to tolerances. Implement quality control checks at each stage to uphold Victorian standards‚ ensuring the final output meets regulatory and safety requirements effectively.

7.3 Post-Completion Checks

Post-completion checks ensure all work meets Victorian standards and tolerances. Conduct thorough site inspections and testing to verify compliance. Review documentation for accuracy and completeness. Identify and address any defects or non-compliance issues promptly. Ensure all regulatory requirements are satisfied before final handover. These checks are critical for maintaining safety‚ quality‚ and adherence to standards‚ providing assurance that the project meets expectations and industry benchmarks.

![]()

Common Mistakes and How to Avoid Them

Common mistakes include misinterpreting standards‚ inadequate quality control‚ and poor documentation. To avoid these‚ ensure thorough training‚ regular audits‚ and clear communication throughout the project lifecycle.

8.1 Misinterpretation of Standards

Misinterpretation of standards often arises from unclear guidelines or lack of training. Common issues include incorrect application of tolerances or ignoring specific regulatory requirements. To mitigate this‚ ensure thorough training‚ use clear documentation‚ and regularly reference official standards; Misinterpretation can lead to non-compliance‚ reputational damage‚ and safety risks. Encourage open communication and provide accessible resources to help professionals understand and apply standards correctly. Regular audits and feedback loops can further minimize errors and improve overall compliance levels effectively.

8.2 Inadequate Quality Control

Inadequate quality control can lead to deviations from established standards‚ resulting in non-compliance and potential safety risks. Insufficient inspection processes‚ poor documentation‚ and lack of trained personnel are common contributors. Regular audits‚ detailed checklists‚ and continuous training can help address these issues. Implementing robust quality control systems ensures adherence to standards and minimizes errors. Without proper oversight‚ even minor oversights can escalate into significant compliance failures‚ emphasizing the importance of rigorous quality management practices.

Case Studies and Real-World Examples

This section highlights real-world applications of standards and tolerances in Victoria‚ showcasing successful implementations and lessons learned from non-compliance. Practical examples illustrate compliance outcomes and challenges.

9.1 Successful Implementation of Standards

Victoria’s adherence to rigorous standards has led to exemplary projects‚ showcasing best practices in construction and infrastructure; For instance‚ the Melbourne Metro Tunnel exemplifies how strict tolerances ensured structural integrity and safety. Collaboration between engineers and regulators‚ guided by the Victorian Building Authority‚ resulted in a project that met both functional and aesthetic goals. This success underscores the importance of aligning innovation with compliance‚ achieving long-term sustainability and public satisfaction.

9.2 Lessons Learned from Non-Compliance

Non-compliance with standards in Victoria has led to costly rework and legal penalties across various projects. For example‚ deviations in construction tolerances caused structural issues in several buildings‚ highlighting the importance of strict adherence. These cases emphasize the need for rigorous quality control and understanding of regulatory requirements. Proactive audits and updated training programs have since been implemented to prevent similar failures‚ ensuring accountability and fostering a culture of compliance.

Future Trends and Updates

Victoria’s standards are evolving with technological advancements and regulatory updates. Emerging technologies and tools‚ like AI-driven compliance systems‚ are expected to enhance adherence and streamline processes for professionals and industries.

10.1 Emerging Technologies and Standards

Emerging technologies are reshaping Victoria’s standards landscape. AI-driven compliance systems and automation tools are being integrated to enhance accuracy and efficiency. Advanced data analytics and real-time monitoring are improving adherence to regulatory requirements. Innovations in construction technologies‚ such as 3D printing and smart materials‚ are setting new benchmarks for quality and sustainability. These advancements are supported by updated standards‚ ensuring Victoria remains at the forefront of technological adoption and compliance in various industries.

10.2 Updates to Existing Regulations

Victoria regularly updates its regulatory framework to align with industry advancements and address emerging challenges. These updates often include stricter compliance measures‚ revised tolerance levels‚ and new guidelines for specific trades. The Victorian Building Authority plays a key role in implementing these changes‚ ensuring they enhance safety‚ sustainability‚ and quality. Professionals must stay informed about these updates to maintain compliance and adapt to evolving standards. Continuous monitoring of regulatory changes is essential for meeting current requirements effectively.

Compliance with standards and tolerances in Victoria ensures safety‚ quality‚ and regulatory alignment. Understanding these guidelines is crucial for professionals to uphold excellence and public trust effectively.

11.1 Summary of Key Points

Standards and tolerances in Victoria are crucial for ensuring safety‚ quality‚ and regulatory compliance. They provide clear guidelines for professionals‚ helping maintain consistency and integrity. Adherence to these standards fosters public trust and confidence in services and products. The Victorian Building Authority plays a key role in enforcing these regulations‚ ensuring that all construction and trade practices meet required benchmarks. Compliance not only safeguards public safety but also upholds the reputation of industries operating within Victoria.

11.2 Final Thoughts on Compliance

Compliance with standards and tolerances in Victoria is non-negotiable‚ ensuring safety‚ quality‚ and legal adherence. It fosters trust and professionalism‚ safeguarding public welfare and industry integrity; Non-compliance risks penalties‚ reputational damage‚ and potential harm to users. Prioritizing compliance demonstrates accountability and commitment to excellence‚ upholding Victoria’s high regulatory benchmarks and fostering a culture of integrity across all sectors;